DM Bands® – Naturally Sustainable … Naturally!

Natural Rubber – Sustainable, Compostable, Biodegradable & Environmentally Friendly

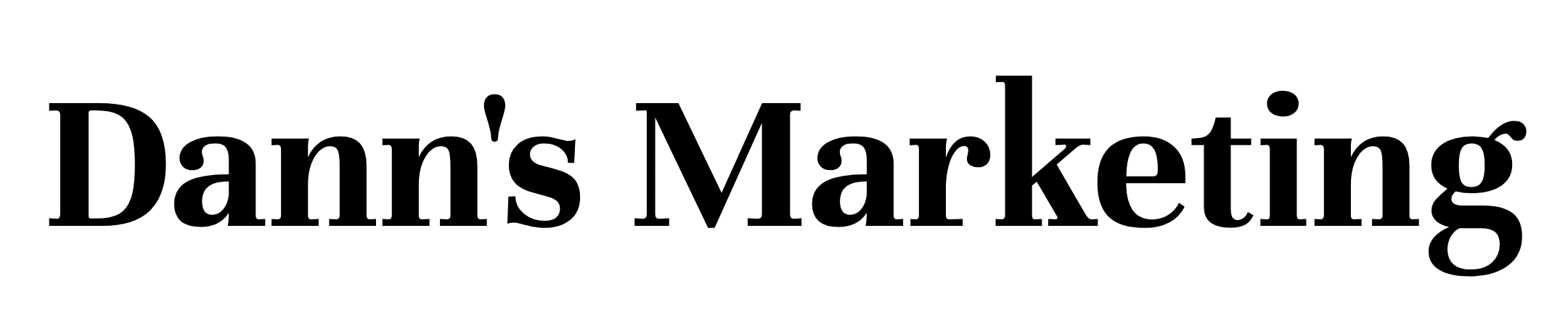

DM Rubber Bands® are made from superior grade natural rubber 95% pure with food grade pigments.

The rubber is produced from the sap of rubber trees from commercial growers. Rubber trees produce this sustainable, renewable and biodegradable resource to make DM Bands®.

DM Bands®

-

Sustainable Resource

-

Sustainable Manufacturing

-

Biodegradable & Compostable

-

Multi-use Product

After 6 years rubber trees are considered mature enough to be harvested for sap. Each tree has a production life-span of approximately 18 years after which the trees are replaced. The distinctive timber is often used to make furniture, laminated beams etc. The sap is harvested by a means called tapping, where the bark is carefully censured by a knife or modern mechanical device whereby the sap flows into a collection container.

DM Bands® only source from Veritas & Lloyds ISO 9001 producers, and monitors this with regular visits to Thailand and Malaysia. This is to ensure guidelines to Sustainable Natural Rubber production are followed:

- Natural environment;

- Economic responsibility;

- Social responsibility; and

- Environmental responsibility.

DM Bands® ensure all our manufacturers meet Australian working environment standards. Only ISO accredited manufacturers are used to produce to our products and where necessary customised production procedures are introduced.

Packaging: Cartons are SGS certified materials and carry the FSC mark of responsible forestry

Poly bags carry the LDPE 4 logo of recyclable plastics. We are currently working with suppliers to produce fully biodegradable packaging.

DM Bands® were the ideal replacement for Jute Hemp twine for bunching vegetables. Both being NATURAL plant based products that biodegrade fits well with the fresh produce mantra of growers.

Certification

DM Bands® are the only rubber bands tested for biodegredation and composability as certified by STRI 'Scientific & Technological Research Institute'.

DM Bands® have the added benefits of being easy to use and clean. Jute fibre was/is difficult to use and can often be mistaken for hair.

DM Bands® are the ideal product for bunching vegetables and flowers:

- they do not damage the produce;

- they hold produce together well in cool storage, in transit and on display;

- easy to use and quick to apply;

- available in a variety of colours, sizes and custom print.

This makes for environmentally responsible packaging that:

- is easily disposed of in green waste bins, home compost and general waste;

- is minimalist packaging;

- has brand awareness/marketing;

- can be repurposed in the home.

Tested in the laboratories, our horticultural grade bands have a high percentage of natural latex which is food safe and also passes all other known World standards.

DM Bands® are not only used to bunch vegetables, they are often re-used in the household - in the home office, kitchen and garage to tie, close and bunch. DM Bands® can be used again and again until they wear out and break.

Being compostable DM Bands® can be put into compost to enrich soil.

Remember, DM Bands® , being biodegradable, are not made to last - they will break down naturally due to environmental exposure.

-

Sustainable Resource

-

Sustainable Manufacturing

-

Biodegradable & Compostable

-

Multi-use Product

After 6 years rubber trees are considered mature enough to be harvested for sap. Each tree has a production life-span of approximately 18 years after which the trees are replaced. The distinctive timber is often used to make furniture, laminated beams etc. The sap is harvested by a means called tapping, where the bark is carefully censured by a knife or modern mechanical device whereby the sap flows into a collection container.

DM Bands® only source from Veritas & Lloyds ISO 9001 producers, and monitors this with regular visits to Thailand and Malaysia. This is to ensure guidelines to Sustainable Natural Rubber production are followed:

- Natural environment;

- Economic responsibility;

- Social responsibility; and

- Environmental responsibility.

DM Bands® ensure all our manufacturers meet Australian working environment standards. Only ISO accredited manufacturers are used to produce to our products and where necessary customised production procedures are introduced.

Packaging: Cartons are SGS certified materials and carry the FSC mark of responsible forestry

Poly bags carry the LDPE 4 logo of recyclable plastics. We are currently working with suppliers to produce fully biodegradable packaging.

DM Bands® were the ideal replacement for Jute Hemp twine for bunching vegetables. Both being NATURAL plant based products that biodegrade fits well with the fresh produce mantra of growers.

Certification

DM Bands® are the only rubber bands tested for biodegredation and composability as certified by STRI 'Scientific & Technological Research Institute'.

DM Bands® have the added benefits of being easy to use and clean. Jute fibre was/is difficult to use and can often be mistaken for hair.

DM Bands® are the ideal product for bunching vegetables and flowers:

- they do not damage the produce;

- they hold produce together well in cool storage, in transit and on display;

- easy to use and quick to apply;

- available in a variety of colours, sizes and custom print.

This makes for environmentally responsible packaging that:

- is easily disposed of in green waste bins, home compost and general waste;

- is minimalist packaging;

- has brand awareness/marketing;

- can be repurposed in the home.

Tested in the laboratories, our horticultural grade bands have a high percentage of natural latex which is food safe and also passes all other known World standards.

DM Bands® are not only used to bunch vegetables, they are often re-used in the household - in the home office, kitchen and garage to tie, close and bunch. DM Bands® can be used again and again until they wear out and break.

Being compostable DM Bands® can be put into compost to enrich soil.

Remember, DM Bands® , being biodegradable, are not made to last - they will break down naturally due to environmental exposure.

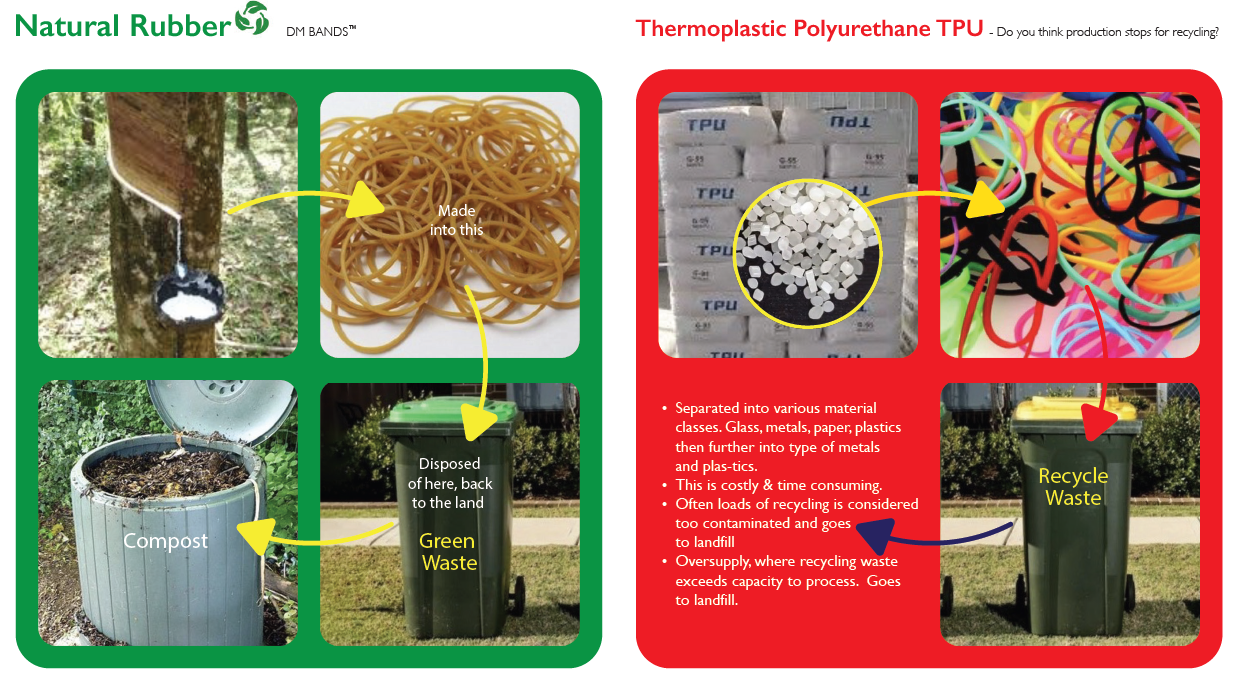

ELASTIC BANDS – Natural vs. Chemically Produced

Federal Government undertakes to phase out unnecessary plastic packaging by 2025!

Before doing a comparison it is important to note APCO Australian Packaging Covenant Organisation have been given the task of reducing plastic waste by 2025 because Australia simply does not have the infrastructure to process recycled plastic. Most of this plastic waste was processed overseas but that is no longer the case.

Australian recyclable plastic was shipped to India and China for recycling but even these massive economies cannot process the shear volume of plastic that needs to be recycled.

Recycling bin: While Councils make it clear what can and cannot be placed into recycled bin, most people do not recycle correctly. Recycled plastic is required to be cleaned and separated before being placed in the bin. Often this just does not happen so the load is considered contaminated and ends up in general waste (landfill). Moreover, there just isn’t the capacity to process it! So why have this preoccupation with recycling if it does not need to happen?

Natural Rubber DM BANDS®

NATURAL – From tree to soil

Rubber bands are derived from trees that have been sustainably farmed for a century. Latex sap is a 100% natural plant based product. Food dyes are used to provide colour. The printing ink used is also certified food grade.

SUSTAINABLE

The rubber trees have a natural life cycle in a plantation where they are harvested for sap and later used in used in the timber industry for furniture. Moreover the trees capture and store Co2 and every tree helps minimise global warming.

COMPOSTABLE

No need to recycle! There is no need to recycle these bands as they are biodegradable and compostable.

DM Bands® bands will break down in sunlight on their own, through enzyme a natural microbe action and so they can also be placed in green waste bins. This has been laboratory tested in compliance with;

AS/NZS ISO14021:2000 Type II environmental labelling.

- Available in many colours and sizes;

- Environment friendly

- The most minimal volume packaging available;

- Non toxic, SGS tested for heavy metals & chemical residues to global standard;

- Can be-purposed in the home;

- Eventually crumbles to dried organic latex like any other plant based product back to the land, in no more than 3-5 months;

- Can be place in either the home compost bin, Green Waste bin or even hard rubbish (collected by the local Council). Either way, DM Bands® end up decomposing into the soil naturally.

CERTIFICATIONS

- BUREAU VERITAS: European Chemicals ECHA, REACH

- SGS laboratory Food Grade Certification. BPA free

- SGS tested for heavy metals

- TISTR biodegradation in compost tested

TPU ELASTIC BANDS – Chemically produced bands

Thermoplastic Polyurethane is a chemically produced plastic C3H8N2O – ethylurea; N-ETHYLUREA;1-Ethylurea; Urea, ethyl-;Urea, 1-ethyl-; POLYURETHANE; ethyl urea; Urea, N-ethyl-.

Requires chemicals to be made then mixed together to produce the plastic pearls pictured below. These are melted and extruded into tubes to be sliced into bands.

Benefits:

- Available in many colours

- Made of 50% recycled and 50% non-recycled plastic

- Non toxic

- Can be printed

- Biodegradable in 3-5 years

- Easy to use

- Should not be placed in Council green waste bins;

- Should not placed in home compost bins;

- Consumers are unlikely to dispose of in Council recycle bins;

- Slow to degrade but does so within an easily attainable Australian Standard guidelines set by the ABA (Australian Bio- Plastics Association) a Self Regulatory body. That period is 3-5 years . Note that after 45 days DM Bands® have degraded by a third.

- Click here to read more about biodegradability of natural rubber – https://www.ablison.com/is-tpu-biodegradable/

TPU should not be confused with bioplastics. When organic matter such as starch or maize is added, it is this organic matter that assists in decomposing the plastic in compost. Further chemical additives are required to be mixed into the compost to assist the decomposition by increasing compost temperature. Even after all these measures to make plastics decompose the process of biodegradation is too lengthy.

The Australian Standards should be reviewed based on the percentage of bioplastic decomposition over a test period of 180 days.

Future issues: Where future bio-plastics in green waste volume is greater than the organic matter required to decompose it!

Where does it all go or end up? Does it really get recycled or do they just make more bags of new product ?

- Multiple factories required to produce end product.

- Good quality agricultural land needed to grow starch producing plants. So plastic can qualify as bio-plastic as per AS Australian Standard established under the self regulated ABA Australian Bioplastic Association.

As as January 2025, TPU bands cannot be placed into household Council recycle bins and have not been approved for use by retail supermarkets.

END OF LATEX PRODUCTION

SUSTAINED MANUFACTURING